In woodworking, an oscillating spindle sander will work to engrave the wooden materials in different shapes. This sanding drum is a holy grail to save time also. Hence, achieving excellence to drive this tool requires some time.

It will often be used for commercial purposes and finish any hard project with an excellent look. It’s a universal truth that without hard work and patience, nothing will come in handy to you.

Also Read: What Is A Oscillating Spindle Sander

That’s why we attach here some basics of how to use oscillating spindle sander safety. So, learn to know more about becoming an expert on this.

- Oscillating Sander Parts

- How To Use A Spindle Sander Safety For Step by Step

- Requirement of Sanding Sleeves

- Step 01- Do Prepare All The Equipment

- Step 02- Put A Mark On The Wooden Pieces

- Step 03- Choose The Exact Drum Size

- Step 04- Attach The Sandpaper With The Drums

- Step 05- Now Start The Sanding

- Quick Tips For Safety

- Frequently Asked Questions (FAQ)

- What Is The Best Spindle Sander Overall?

- Is it Necessary To Use A Dust Port On A Spindle Sander?

- Are There Any Replacement Parts Available On The Sander?

- Bottom Line

Oscillating Sander Parts

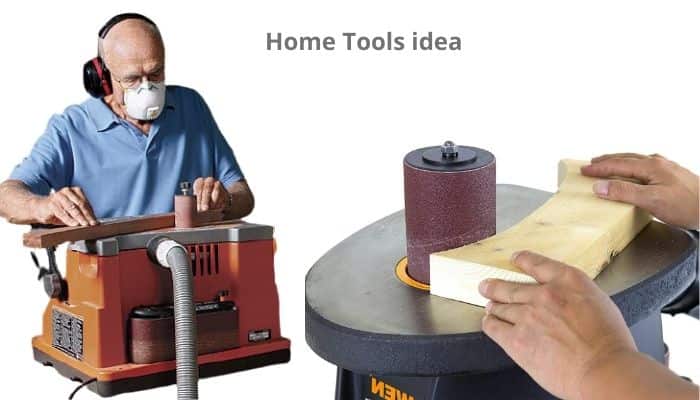

In general, the spindle sander uses some basic parts to work. Each of the parts works individually to shape a wooden piece. With the constant ups and downs, the sander will rotate the wood varnishes more smoothly.

Oscillators are used to move side to side for sanding the wood. It is great for cutting back trims at floor level. Comparatively, the orbital sander has a deck that rotates around the workpiece by circulating it. But the technicians and woodworkers found this rotating spindle much easier to use than other sanders.

Additionally, this benchtop sander has ten basic parts-

- Power sources

- Tabletop

- Spindles

- Sanding sleeves

- Throat plates

- Upper spindle washer and hex nut

- Rubber sanding drums

- Sanding drum storage pegs

- Dust port

- On/off switches

Some models have dust collection and on-storage functions also. An oscillating spindle sander uses the spindles to sand the edges of boards. Using the spindle, those wooden pieces get the sharper looks ever.

By using the power port, the sander gets the electric connections from the sources. You must have understood that this benchtop sander won’t provide a ton of H.P to run the deck. Many good machines require using only ¼-½ H.P on average. Hence, it didn’t need to run more than this above.

The best part of this spindle sander had a flat and sleek tabletop. It is known as the workhorse for the oscillating sander. Typically, the tabletop is a rubber lined and steel cast cylinder that fits upon the spindle.

Moreover, this tabletop makes a base to rotate the spindle clockwise with the help of a nut. The spindle then works to compress the drums and allow them to extend slightly. Holding the sander slip in place is another reason to attach this to the machine.

Check out the products and choose one that’s right for you!

Best Image | Product Title | Best | Speeds | Price |

WEN 6510t Oscillating Spindle Sander | Best Oscillating Spindle Sander | 58 oscillating per minute | ||

Rikon Oscillating Spindle Sander | Best Benchtop Spindle Sander | 29 oscillating per minute | ||

Shop Fox W1846 Benchtop Oscillating Spindle Sander | Best Budget Spindle Sander | 58 oscillating per minute | ||

Triton TSPS450 Oscillating Spindle Sander | Best Portable Spindle Sander | 58 oscillating per minute | ||

Grizzle Oscillating Spindle Sander | Best Bolt & Spindle Sander | 58 oscillating per minute |

How To Use A Spindle Sander Safety For Step by Step

Spindle sander safety can be used on some quick steps. No matter whether you’re a beginner or intermediate, our below steps will give you a clear conception of it. So here are the five vivid steps to elect excellence in these affairs.

Requirement of Sanding Sleeves

- 60 grit to 220 grit

- Best to use a 4-inches sanding sleeve. This is a standard size that fits on the sander adequately.

Step 01- Do Prepare All The Equipment

How you use a spindle sander depends on the techniques that you need to follow. Before you’re going to start, prepare all the pieces of equipment that you want to sharpen.

All in all, it’s vital to make sure that you’ve got enough spindles on your hand. The spindles should be perfect. Additionally, cover the workplaces with old clothes or safety clothes. We’ll talk about why you need to arrange this in-depth on the safety tips part.

Step 02- Put A Mark On The Wooden Pieces

After collecting all the wooden pieces, put a mark on them. This will help you identify the circumference and depth.

We advised you not to rely on the bare eyes to measure the wooden pieces. If you somehow forget to put the mark on the workpieces, the entire work will seem to be poor. For this reason, you may have to finish the job inaccurately.

Step 03- Choose The Exact Drum Size

An oscillating spindle sander has numerous sizes of the drum. With the continued rotation of that drum, the spindle sander will make a way to varnish the wooden slices. The right measurement here opts to fit the wooden slices towards the drums correctly.

So it’s obvious to figure out the right measurement of the curves to fulfill the task righteously. You can assess the drum size by using a measuring tape or whatever for metering. Try to start with the smallest parts on your first attempts instead of the larger ones (especially if you’re a novice).

Step 04- Attach The Sandpaper With The Drums

Before using an oscillating spindle sander, ensure that the rubber drum is attached to the sandpaper. Attaching the sandpaper will anticipate the work half done. Further on, don’t forget to manage the right size along with the settled grit.

Step 05- Now Start The Sanding

After finishing all the preparation, I am now getting ready for sanding. Sanding the wooden pieces needs to be as light as possible. Not to mention, here, you need to be patient regarding doing the job within a snap.

First, remove the spindle from the basement. Then put the drums over the tabletop. Remember, after putting on the drum inside the machine; you need to tighten the drums as much as possible. Otherwise, there is a high chance of the workpieces slipping away from the drums.

Keep it up and tighten the drums clockwise. Afterward, switch on the power button of the spindle sander. Then allow the rotating drums to sand the wooden pieces by themselves. Again, do not push or force the pieces on your own. Take it easy and hold the workpieces in one direction. Check out the oscillating edge belt spindle sander speed; is it doing the job appropriately or not.

Sanding The Straight Edges

You need to keep the pieces held until it will finish the area you’ve marked often. Once it gets complete, reach the borderline of the marks, then move or change the directions. Don’t forget to inquire that the sander creates an equal edge on each area.

Thus, you can make a perfectly straight cut by using this sander. One thing you must have to be careful about is not to get pressurized, the drums make a cut. The more time you’ll invest in this occurrence, the more perfection you’ll attain.

Sanding The Curves

By using an oscillating sander, you can make different curves. After cutting the curve, place the boards towards the tabletop. Keep a safe distance from the drums and turn on the motor.

Don’t try to fix the wooden board forward until you’ve noticed the curve is getting close to the drums. Allow the drums to keep sanding the edges once you’re sure that cut lines are smooth and even.

Quick Tips For Safety

Remember that knowing the safety issues is equally crucial to learning how to use a spindle sander. Because without knowing them, you won’t be aware of what to do and what you should have to skip.

We came to know of oscillating spindle sander reviews as most of them face mishaps, inner loss, or lack of guidance. To avoid those issues, ensure to follow the tips below.

Frequently Asked Questions (FAQ)

What Is The Best Spindle Sander Overall?

Nowadays, there are tons of spindle sanders available in the market. But the WEN 6510t Oscillating Spindle Sander is the best, according to our research. They’re good enough and ideal due to getting some special features and excellent customer rating

Is it Necessary To Use A Dust Port On A Spindle Sander?

Of course, a dust port is necessary to use on the spindle port. The dust port is usually used to collect debris and sand dirt from the machine. It’s a vital feature you need to consider, as they’d collected the messes abruptly.

Are There Any Replacement Parts Available On The Sander?

Yes, there are many replacement parts available on the sander. You can check out any local shops to ensure that the brands you’re using also have the parts.

Also Read: Top 12 Solution Of The Problem For A Oscillating Spindle Sander

Bottom Line

To achieve the perfect, smooth, and good sanding operation, the best way is to use the right grits. An even look must have attained on how successfully you’ve to sand the workpieces.

In other words, nothing is more useful than sanding the edges with a coarse grit around 60-100. Then go through the medium sanding using 120-180 grits. At the end of the work, sand the slices with a fine-grit around 220 or above.

So, hope you’re getting successful on the mission of how to use oscillating spindle sander safety. Experiment now.

1 thought on “How to use Oscillating Spindle Sander safety”